views

The Benefits Of Automated Plastic Injection Mold Design

When performed by a skilled professional plastic injection mould manufacturer employing modern, automated technology, plastic injection molding procedures are quick, efficient, and accurate. Each manufactured component will be identical to the initial design files and other pieces in the order, thanks to the use of superior equipment and automation technologies.

Automated plastic injection mold design technology can ensure that the same quantity of material is injected into the mold every time, at the same pressure, and at the same length of time, as well as a slew of other factors. In this medium post, the merits and a wide variety of applications of these systems will be addressed in detail.

Automation and Robotics Benefits in Plastic Injection Molding

Because automated systems can handle most components of the job without operator intervention, automation is becoming more common in all types of production. As a result of this,

Machines are used more efficiently. Interconnected automated systems communicate with one another via a centralized control system. This sort of injection molding equipment will create that analytics will allow users to find areas for improvement as well as warn human operators when components fail or require inspection.

Increased manufacturing speed: Robotic systems can complete tasks without being interrupted.

Automated systems that are well-maintained may run 24 hours a day, seven days a week, resulting in higher per-unit productivity and faster order fulfilment.

Labor costs are lower: Robotic systems can do tasks that traditionally needed numerous people, allowing facilities to take on more orders while employing fewer workers. Lower direct labor expenses, as well as indirect cost savings, leads to lower total project costs.

A fabrication that is more sustainable. Automated machines generate less waste from rejected or deformed components because they produce enormous volumes of goods with low error rates.

Injection molding by hand vs. injection molding by machine

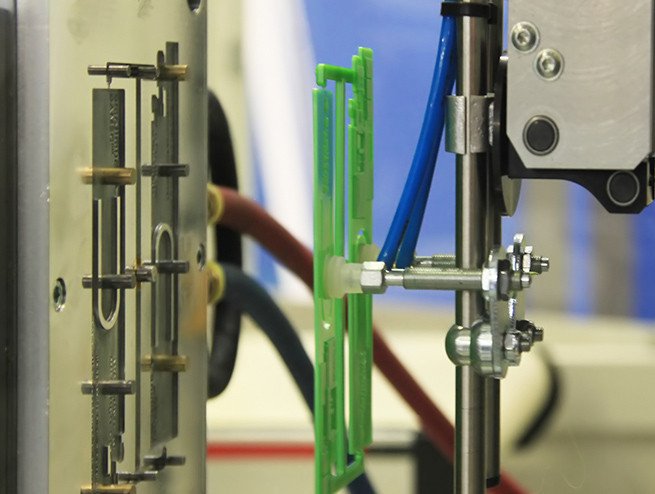

Outside of the direct molding process, introducing automation to cheap injection molding operations provides several advantages. The material management component after the mold opens is one of the fundamental distinctions between traditional injection molding and automated injection molding. Newly molded pieces are delicate and prone to deformation when subjected to pressure. The workpiece can be collected by robotic systems with pneumatic grippers or vacuum-based collecting systems without being damaged or compromised. Tools that have been fine-tuned may also handle items that require overmolding or extra processing.

Automated Plastic Injection Molding Applications

Plastic injection molding that is automated is beneficial in a wide range of industries and applications. Automated procedures are commonly used for the following purposes:

Loading and unloading is a two-step process. If manual techniques are used to load and unload plastic molds for chocolate making equipment, a lot of space is consumed. Robots can establish an ideal working environment in which they can perform efficiently in restricted spaces and load and unload machinery without the danger of human mistakes. In addition, automated machinery employs the same amount of shot material every cycle, resulting in consistent and precise results.

Inspection and quality control using vision. Robotics and automation allow humans to supervise inspection operations. Robots can position pieces, utilize sensors to check for dimensional issues, and so much more.

Assembly / sorting / stacking. After the mold stage, robotic devices may perform difficult jobs.

Welding to assembly assemblies, sorting and organizing components for kits or packaging procedures, and other duties are among them. These features help to decrease the chance of mistakes and expedite the order fulfilment process.

Processes that occur after the primary ones. Secondary activities, such as decoration and labeling, are frequently required for molded items. To conduct these jobs quickly and precisely, smart systems can use side-entry injection molding robots.