views

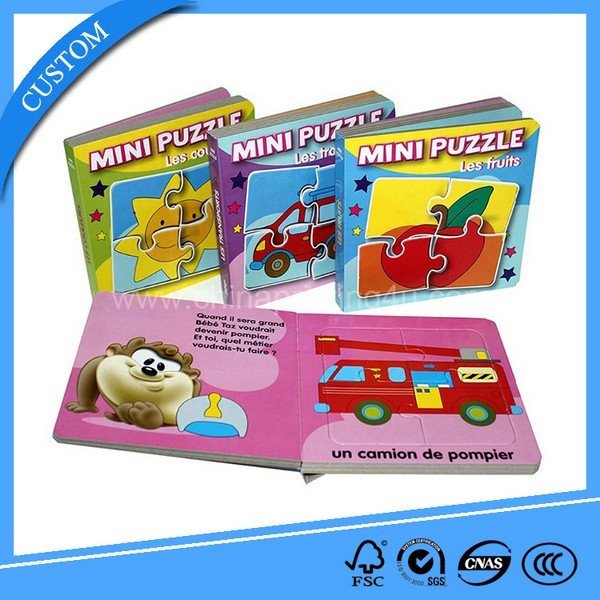

The children's book market is becoming more and more prosperous, as parents pay more and more attention to reading. However, how much do you know about the professional environmental standards for children's book printing?

Now many parents pay more and more attention to the cultivation of their children's reading habits, so they will prepare all kinds of cards, picture books, books and other printed materials for their children. However, if you don't pay attention to and care about the quality of printed materials when purchasing these printed products for children, some printed materials may have a negative impact on children's health to varying degrees.

What kind of printed matter will have a negative impact?

The environmental protection of printed matter cannot be confused with the quality of printed matter. The quality of printed matter refers to the clarity of handwriting and lines and the accuracy of color restoration. The environmental protection of printed matter refers to that readers do not bring health hazards to readers when browsing printed matter.

In this regard, we can analyze the main materials for printing children’s books to read printed materials: paper, ink, glue...

The ink may contain benzene, especially the color ink, which uses a dissolving agent such as benzene. After the new book is printed, the solvent does not volatilize completely, and the reader will emit an unpleasant smell when opening the package. Benzene and toluene are highly toxic liquids with strong odor. They can not only damage the respiratory tract, but also cause acute poisoning and paralysis of the central nervous system. Short term inhalation makes people dizzy and disgusting. Long term exposure may damage the bone marrow, resulting in leucopenia, thrombocytopenia and aplastic anemia.

Another source of pungent odor is the glue used for children book printing binding. Most of the glue used for binding books uses quick drying agent. Generally, this volatile chemical substance will disappear completely after 10 to 20 days. However, the smell cannot be emitted when the books are sealed in the packaging bag, so the readers will still have peculiar smell after taking them into their hands; In addition, some inferior paper and adhesives contain a large amount of formaldehyde, emitting a strong smell. Long term exposure to such chemicals is very harmful to health and seriously affects children's physical development.

Moreover, because children's book habits are different from adults, the heavy metals that may be contained in inferior ink and paper, such as lead, will enter the human body through the child's hands and mouth and affect the child's body. In particular, parents should be reminded that pirated books often use inferior paper, ink and glue to reduce costs. A solid substance test report shows that the lead content of some pirated books is 100 times higher than that of similar genuine books. Therefore, when buying books for children, we should pay special attention to screening pirated books.

To see whether the ink belongs to environmental protection ink and will have a negative impact on the author, we mainly consider the following two points: first, heavy metals. Due to children's book habits, heavy metals in the ink may be inhaled from the mouth. The second is volatiles. The solvents and additives used in ink include aromatic hydrocarbons, alcohols, esters, ethers, ketones, etc. They will evaporate with the drying of the ink and enter the reader's respiratory system.

So what are the main types of environmentally friendly inks?

1. Rice bran ink

Rice bran ink technology originated from Japan. At present, many Chinese printers are also studying it. The main reason is that China and Japan are large countries of rice consumption and production. The rice bran produced in the process of rice is only used as animal feed and is far from giving full play to its maximum value. The development of rice bran oil refining technology and the technological breakthrough of rice bran oil in ink not only maximize the value of rice bran, Moreover, the environmental protection and sustainable development of printing ink have been further improved.

The main advantages of rice bran ink are: low VOC (volatile organic compounds) residue, low migration and low environmental pollution; Rice bran resources are easy to be localized, which is in line with China's national conditions; Rice bran ink has high gloss, less residue of harmful substances in prints and high safety.

2. Soybean oil based ink

The aromatic hydrocarbon of mineral oil in the ink decreases or disappears, but the influence of VOC cannot be avoided. Therefore, soybean oil-based ink in which some mineral oil is replaced by soybean oil appears. After the soybean oil is slightly purified, it is mixed with pigments, resins and other additives. Soybean ink also has many advantages: abrasion resistance, no irritating smell, light and heat resistance, easier recycling, wide color and so on. In addition to soybean oil, other vegetable oils can also be used, such as flax oil.

3. Water based ink

Water based inks do not contain volatile organic solvents, and only need to be diluted with water in printing. Therefore, the water-based ink greatly reduces the emission of VOCs and avoids the pollution of volatile organic compounds. At the same time, it significantly reduces the harmful substances left on the surface of printing products, and belongs to one of the ink types that most meet the green environmental protection standards. In addition, the application of water-based ink can also reduce the fire hazards caused by static electricity and flammable solvents, and reduce the residual solvent smell on the surface of printed matter. Therefore, the application of water-based ink in food packaging, children's toy packaging, tobacco and alcohol packaging, children’s book packaging and other fields is becoming more and more common.

Facebook Conversations