views

The Role of an agile and cloud-based ERP in Chemical Manufacturing

Modern Manufacturing

In recent years the chemical industry has witnessed a radical change in production methods. With technology gaining more attention in almost every sector, including manufacturing and distribution, business leaders need to upgrade their technology stack and outdated processes to meet the changing demands of the market. A rapid transformation of the Chemical manufacturing value chain is required to improve efficiency, productivity, quality, precision, pricing, and more.

While “Complexity” serves no good for business, it has been part and parcel of the chemical industry for decades. Many companies suffer from siloed department structures, disparate systems, inefficient data management, and a lack of streamlined processes due to lack of an agile ERP solution. These have all helped create roadblocks that hurt the bottom line of the business. Most companies don’t realize the gravity of the issue until the lack of integration between the floor and functional areas rears its head. As a result, it’s been easy for orders to get lost and product quality to suffer thanks to suboptimal production runs or poor capacity planning.

Chemical manufacturing companies need to take action by redefining their business models and re-evaluating their IT roadmaps. Chemical companies invest in transformation projects such as integrating a cloud-based ERP solution with operations to streamline processes, drive collaboration and efficiency, and offer much more informed decision-making.

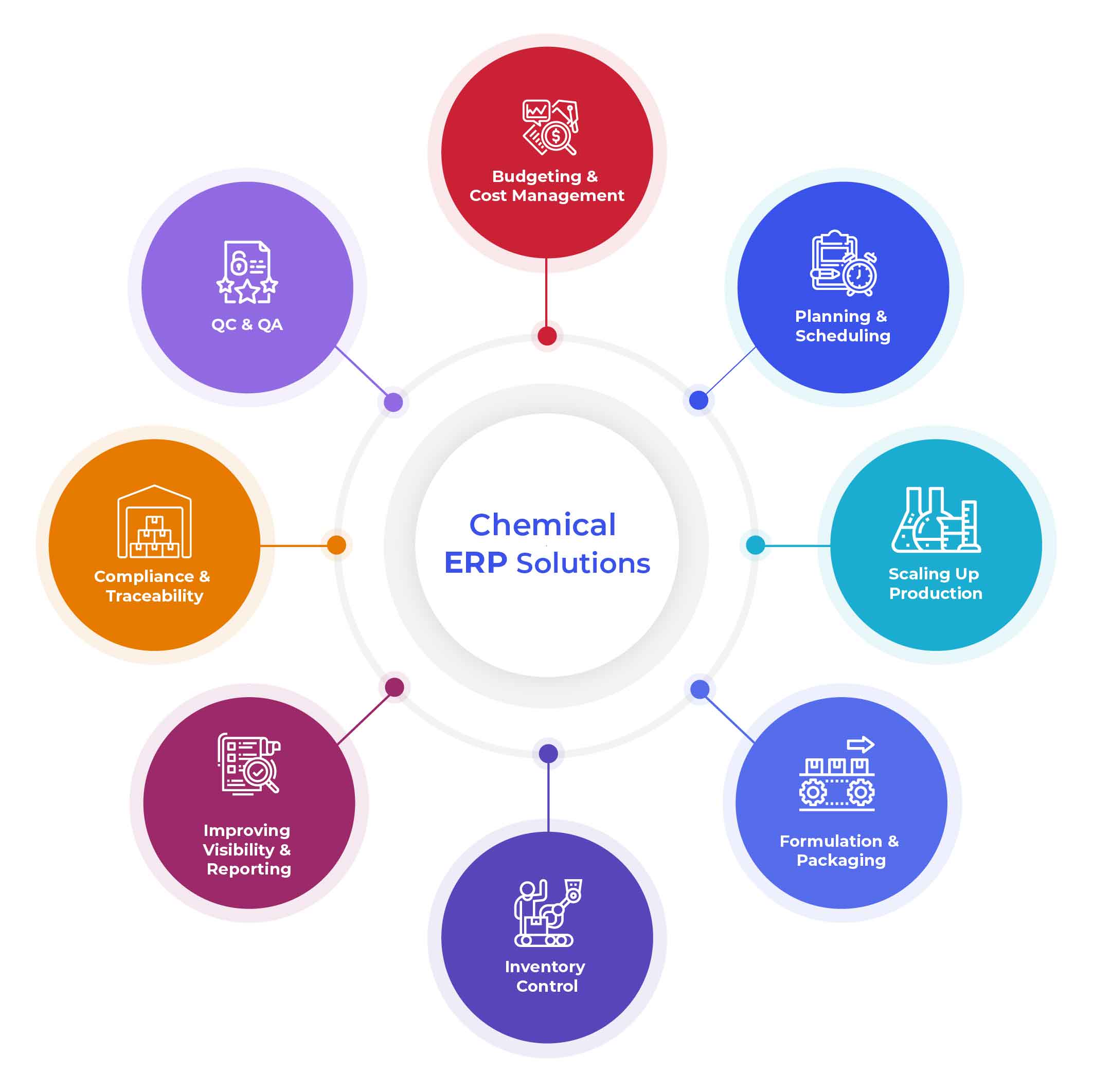

FIGURE 1Agile ERP Solutions in Various Phases of Chemical Manufacturing

Unforeseen Circumstances: COVID-19

The COVID-19 pandemic caused havoc, severely impacting every industry. The functioning of departments such as production and shipping became increasingly challenging. As a result, hundreds of companies had to scale down their manufacturing operations by as much as 40-60%. With such fewer raw materials being supplied, by February, the global production of chemicals had dropped by 2.4%.

The drop in business severely impacted revenue in Chemical companies. On top of that, transportation costs have gone up, and priority has shifted to essentials. This sort of financial pressure has forced companies to downsize the workforce, yet having to continue the business, which now is enforcing rapid technology transformations at an optimal cost.

An Agile ERP in Manufacturing

Unlike many other sectors, businesses in the chemical industry may not be able to stop production and send workers home. On the flip side, many chemical companies are pivoting operations to meet the demand of the market.

Add to this, a unique share of challenges that already exist for the chemical industry, including issues like

- Fluctuating prices of raw materials and their impact on margins

- The need for constant product innovation

- Increasing risks in supply chain & manufacturing

- Tightening regulations

- Market uncertainty, budget & controlling costs

- Difficulty in resource management

To overcome these complexities, companies need to possess a detailed overview of the market to identify the shifting customer dynamics and plan appropriately. Cloud-based ERP systems for manufacturing can help identify market needs, shape the manufacturing processes, and finance a chemical company’s financial business processes.

6 Ways Implementing ERP will Improve Operations in Chemical Manufacturing

01.Improved Visibility

An agile ERP unifies data across departments, increasing the visibility of information across an organization, and eliminates unnecessary infrastructure costs while providing higher data security. Within a chemical company, process automation add-ons to the cloud ERP eases resource overload by optimizing workforce utilization on the shop floor. All departments across the company, including inventory management, purchasing, accounting, human resource management, production, and finance function together with a minimum breakdown and maximum clarity in operations. Agile cloud-based ERP systems for manufacturing can help a chemical company access real-time data on a uniform platform and boost throughput to reduce downtime.

02.Enhanced Flexibility

As market demand fluctuates, there is a growing need for increased adaptability in the manufacturing and supply chain, enabled using the right ERP solutions. A Chemical company can share important updates and revised manufacturing plans/ schedules utilizing the supply chain planning system to plan stock availability. An agile ERP system for chemical manufacturing should follow a tiered approach comprising

- secure database

- simple user interface and higher accessibility

- easy integration with external tools

The Chemical industry has a unique set of functional requirements to accommodate Environment health and safety and OSHA regulations. Cloud ERPs give Chemical companies the flexibility to customize the solution to suit their needs without migrating data or altering the entire piece of software.

03.Better Collaboration and Transparency

Data associated with the right ERP leads to better collaboration across the enterprise. Complex business procedures often are simplified, and simpler processes with no controls are made more stringent due to an ERP implementation project. All modern systems have enough restrictions to enable a disciplined method of functioning, that companies may have missing. A process and rule-based system improves transparency and sets the organization for growth.

04.Better Supply Chain Efficiency

A successful ERP software implementation eases the complexity of supply chain management with better-informed demand and supply management. Data insights collected from a well-designed ERP system for chemical manufacturing can reduce inventory cost, enhance supply chain efficiency, and optimize production processes that, in turn, build a robust supply chain. Building supply chain efficiency has further benefits such as decreasing expenditure on raw materials, increasing profit leading to capital growth for any company.

05.Improved Production

Chemical companies often pay a hefty price if the system they use is lacking functionality. The typical end-to-end chemical production process comprises – scheduling lot production, estimating the cost of the lot produced, recording consumption of raw materials, recording route operations, quality control check on lots, and accurately recording yields. This process exchanges multiple hands and devices. A poorly designed manufacturing execution system can hinder the batches produced, draining resources, and add unplanned costs to the company. All you need is an agile, cloud-based ERP system for chemical manufacturing.

06.Enhanced Customer Service

With the right suite of ERP and CRM solutions, it is possible to fulfill the customer-centric objectives such as understanding the customers’ needs, improving service levels, and enhancing customer experience. An agile ERP that supports companies to attend to their customers’ needs and resolve issues faster ultimately drives customer retention.

Final Thoughts

A Chemical manufacturing company holds its share of challenges. Be it specialty chemicals, bulk chemicals, private-label, co-pack, or a contract manufacturer, having the right cloud-based ERP systems for manufacturing helps to build operational efficiency, bring products to market faster, reduce the cost of operations, be more agile, and responsive to market changes.

Facebook Conversations